WHAT IS CUSTOM PACKAGING

Unlike standard packaging that can be purchased in bulk and is mass-produced, custom packaging is tailored to the individual requirements. Custom boxes are a great way to present your products in an elegant and stylish fashion.

WHY ORDER CUSTOM BOXES FROM US

Duncan Packaging is one of the leading custom box manufacturers in Australia. We are able to supply custom printed boxes in a wide variety of sizes suitable for all types of business such as retail, e-commerce, product packaging, distributors, start-ups and small business. Each project is carried out according to the customer’s requirements, so you can always be assured of the highest quality and most cost-effective solution.

CUSTOM PACKAGING PROCESS STEPS

STEP 1 – UNDERSTANDING YOUR PACKAGING REQUIREMENTS

First things first, we will discuss your custom box requirements and the measurements of the products you need to package. We always keep in mind how we can keep costs to a minimum whilst still providing the top-quality custom packaging we are known for.

Choose the materials for your custom boxes

When creating your custom boxes with Duncan Packaging, a very important step is choosing the right materials for your design. Depending on your individual needs, you can choose from a range of materials such as corrugated cardboard, solid fibre board, paper covered board, bleached board, hi-bulk artboard and many more.

Choose printing & finishing methods

The printing style you choose for your custom boxes is the next important decision you should carefully consider as it will impact on the final product.

As with everything during the process, we will walk you through the options in detail and explain what works best. You can choose from printing styles such as digital printing, screen printing, offset printing (lithography), flexographic printing (flexo) and various finishes such as hot foil stamping, film laminating, embossing / debossing or spot UV varnish.

STEP 2 – CUSTOM BOX QUOTATION

At this point, our sales team passes the specification to our estimating team to create a quote which is emailed to you for your review. Once the quote has been accepted, an estimated production time frame is then mutually agreed.

STEP 3 – PREPARE YOUR ARTWORK

Once we have an understanding of your requirements you can start designing your custom boxes. If it is a simple addition of your company logo/branding in the most visible section, we can do it for you. Otherwise, we will supply a custom box template and artwork guidelines for your graphic designer.

This is the phase between creating of the actual print layout and the final printing. When you order a custom printed boxes, our prepress team sends you a digital proof to check whether they have correctly understood all the details of your order. This process often involves a lot of back & forth until the final specifications have been finalized. Once both the parties are satisfied, and the digital proofs are approved, the next stage begins – that is the manufacturing.

STEP 4 – MANUFACTURING YOUR CUSTOM BOXES

Once we have an approval of the finalised artwork and production has been agreed, a typical production run will often be complete in around 3-4 weeks.

The manufacturing of custom packaging involves printing your artwork, litho-laminating process (if required), die cutting the board and all the other finishing processes.

STEP 5 – DELIVERY

We will ship your custom boxes using the fastest, safest, and most reliable method possible. An appropriate despatch method and carrier will be selected when you order. If your company is based in Greater Melbourne, we can deliver your order for a fixed charge of $35 excl. GST. You are also welcome to organise your own courier or pick up yourself from our factory.

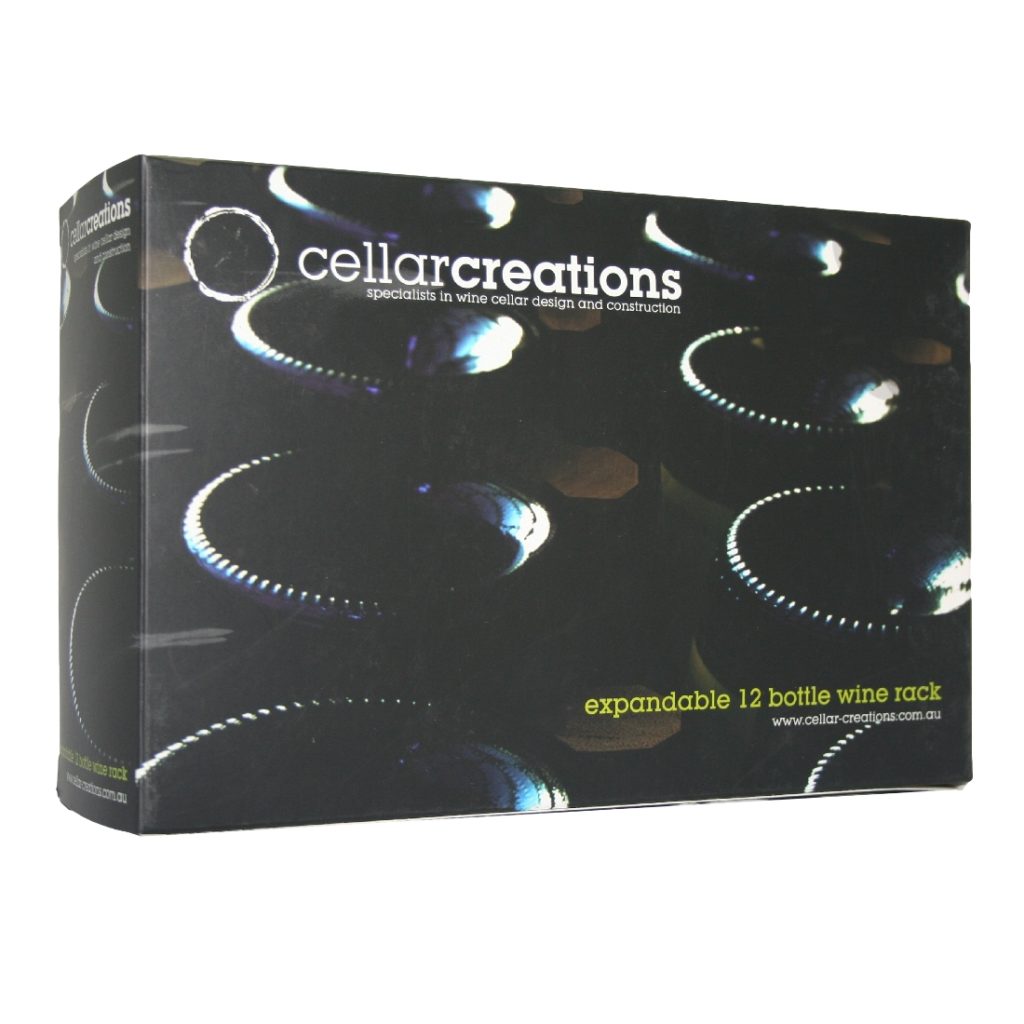

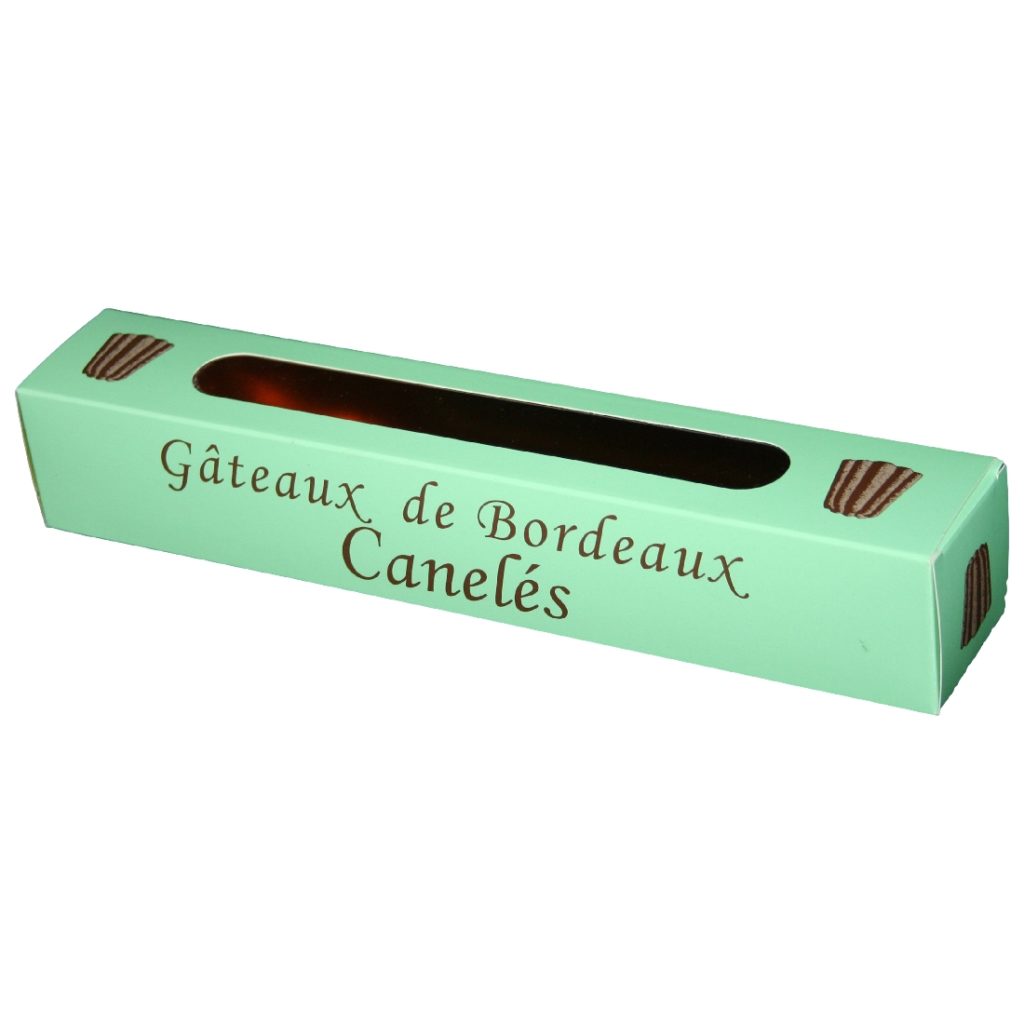

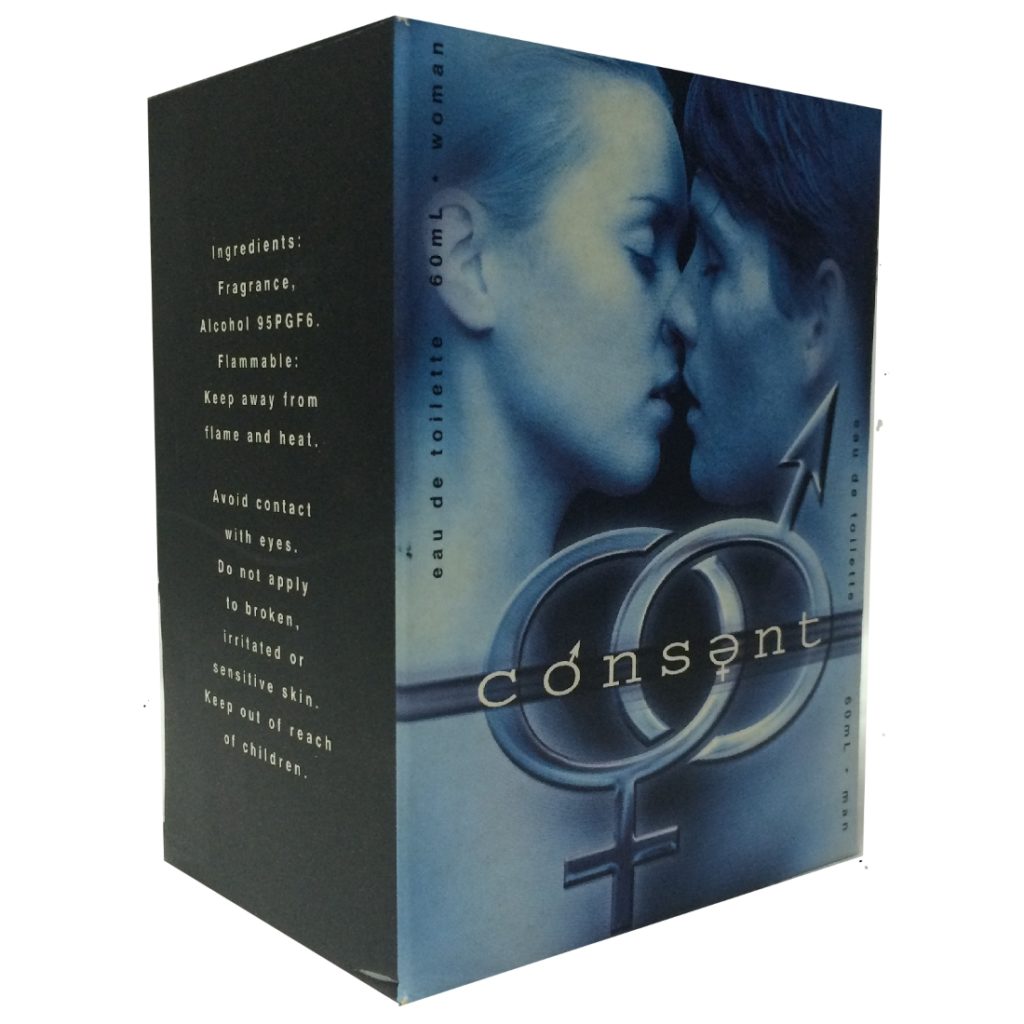

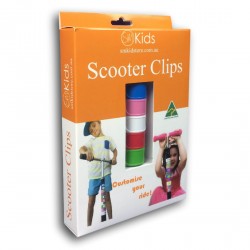

Below are some examples of the different types of custom boxes that we made for our customers.

PLEASE CLICK ON THE SIDE ARROWS BELOW TO SEE MORE IMAGES.